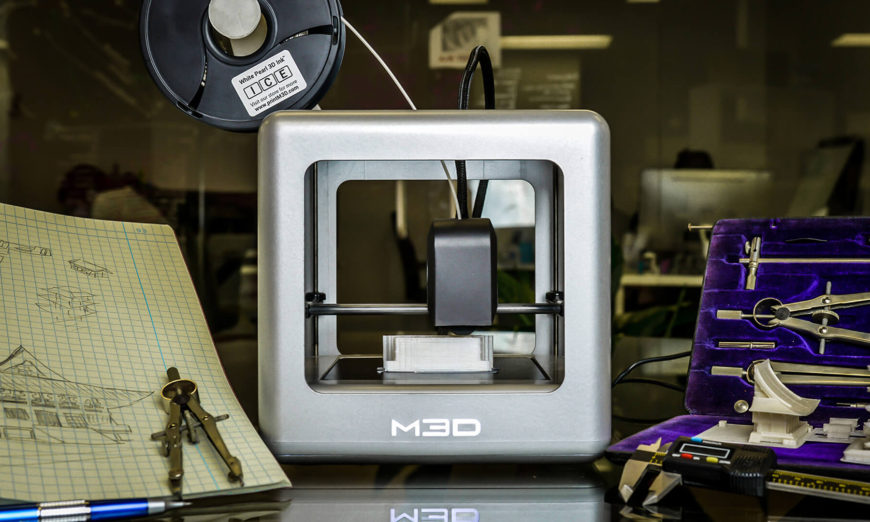

With its sleek, smooth design and a variety of colours to suit your taste, the M3D is one of the leading printers in the consumer 3D printer market. These printers are popular because of their compact size and their easy to use software. Replacement filament is also easily accessible and it is compatible with other third-party filaments. These filaments are made of various plastics and other materials compressed into a size that can easily go through the print head. For photo enthusiasts, 3D printers can be used to create accessories for your camera. Read our past blog article to find out more. There are many 3D models already available on the web that can be downloaded and printed in a matter of hours.

The printer is driven and receives its prints from a computer via USB connection making it compatible with both PC and Mac. The printer software is easy to use and even shows a 3D preview of the design before you begin the printing process. While the print bed of the M3D is relatively small and can be limiting in terms of the size of prints it is capable of creating, it can easily print smaller sized items and can be placed anywhere in your home.

With 3D printers there are many materials available that can be used to create and fabricate 3D models. Two of the most common materials people like to work with are PLA(Polylactic Acid) and ABS(Acrylonitrile Butadiene Styrene). Both are hard plastics that are easy to work with and don’t require too much effort. At Henry’s we carry the PLA filament for the M3D printers as it requires little maintenance and is an easy material for new users.

While PLA is easy to use, it is not the most durable substance, however its affordable price point makes it a great option for new users and printers. ABS tends to be a less brittle material, it is not as environmentally friendly as PLA. PLA is primarily based from Corn Starch and is biodegradable. This means that no matter how much you print or how many attempts it takes, you can be confident that you will not be harming the environment with unnecessary plastic waste.

The M3D printer software offers you the option to select different prints thickness and fills.

These options range from a completely hollow and thin print setting that allows for quick prints, used primarily for prototypes, to a heavy fill that prints a thick honeycomb pattern inside to offer extra support. The mid fill range will print single lines in any weak areas to give limited but adequate support to the structure.

The M3D makes it easy to change filaments and colours to get different effects and appearances. Simply type the 3-character code on the side of the spool into the printer software and the printer will adjust its temperature and print speed accordingly to get the best possible results.

The prints will not happen immediately. M3D prints generally take hours to complete, and some larger, more detailed prints can take a full day. We recommend starting a print when you are going out or leaving it to print overnight. While the printer is relatively quiet, it is still loud enough to disturb light sleepers so we recommend in an area of low traffic.

The M3D is capable of detailed prints, including replicas and sculptures as well as scale models. Replicas of skulls, prototypes, designs, mini structures to develop layouts for homes or even subdivisions.

It has also been useful for printing accessories such as mount adapters, or even lens caps. While it does take a long time and is not convenient, you can print lens caps, covers, mount adapters overnight, and the cost of the materials used in the filament will be a fraction of what it would cost to go out and buy a manufacturer made replacement.